Model No: 553

O.D of casing tube: 610mm

I.D of casing tube : 584.6mm

Wall thickness of casing:12.7mm

Guide device max.Dia:582mm

Reamed Dia: 639mm

Max.O.D. of Normal bit: 553mm

Blocks:4

Weight:895kg

Concentric Casing System With Blocks

Drilling through formations with loose,unconsolidated material always comes with problems such as the bore hole cave-in collapse;How to avoid these problems? With years of field practice and research,Prodrill has developed its Concentric Casing system with blocks applicable for foundation piling with backfill and pebble formations and casing depth within 40 meters.

Concentric overburden drilling System by DTH Hammer which designed to drill and case a hole simultaneously through unstable ground conditions.

The driver bit(Pilot bit , Guide Device) incorporated with a one-time used ring or reusable ring makes a full face head design which significantly improves the penetration rate and hole straightness of drilling. The internal flushing grooves together with the built-in casing shoes gives a good seal to the button of the drilling hole, and thus mini missing the disruption of the surrounding of the drill hole.

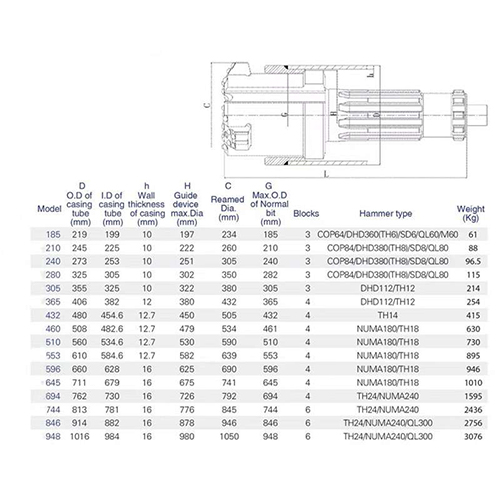

Model NO :185,210,240,280,305,365,432,460,510,553,596,645,694,744,846,948 Concentric Casing System Technical Data:

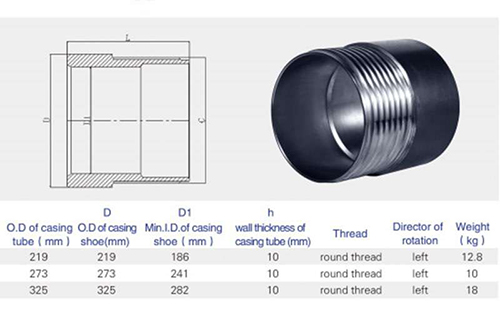

Thread of casing shoe for Concentric Casing System

Welding of casing shoe

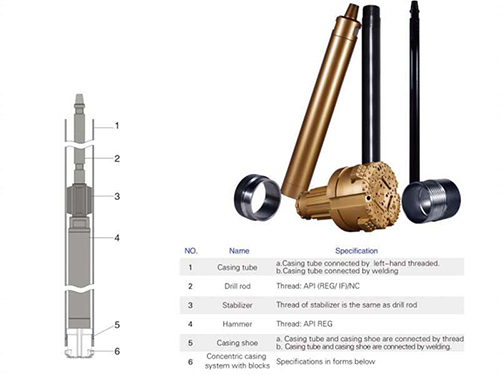

Related Parts List

How to work:

1. Ring bit and casing shoe assembly is welded to casing prior to drilling. Lock the assembly into pilot bit with DTH (Down the Hole) or Top hammer. The pilot bit's upper shoulder engages the shoulder of the casing shoe.

2. DTH or Top Hammer's percussive energy is transferred through the pilot and ring bits, crushing rock. Part of impact energy advances casing.

3. On completion of drilling and casing, the drill string with pilot bit is retrieved by a slight reverse rotation to unlock the bayonet coupling. The ring bit stays in the hole, and can be recovered only if the casing is retrieved

4. Drilling continues to the desired depth in the bedrock using a conventional drilling.

COD610-Concentric overburden drilling System by DTH Hammer

Rock Drill Bits Advantages:

Full face head design for faster penetration and straighter hole less torque is required

Can drill in vertical, horizontal or any direction

Minimize disruption to the drilled hole

Varied ring bit diameters to suit different casing requirement

Contact: Kevin Dai

Phone: 13605749661

E-mail: sales@bloommachinery.com

Whatsapp:+86 13605749661

Add: Hehua Bridge, Yunlong Town, Yinzhou Distric, Ningbo City, ZheJiang Province

We chat